Machined Parts

Our CNC Machines Infrastructure

Machine Specification

- VTL – Hwacheon VT550: With a maximum diameter of 550 mm, this Vertical Turret Lathe ensures precise and efficient turning operations, catering to a wide range of components.

- .

- CNC-Lathe – Jyoti- DX200: With a maximum diameter of 250 mm, this CNC lathe offers high precision for a variety of turning applications, meeting the demands of diverse industries.

- VMC – LMW JVKRAFT: Equipped with a table size of 800 mm * 550 mm, this Vertical Machining Center provides versatile machining capabilities for precise and intricate components.

- VMC – BFW 65 TC40: Boasting a table size of 1200 mm * 850 mm, this Vertical Machining Center enables us to handle larger workpieces while maintaining superior accuracy.

- VMC – LEADWELL: With a table size of 1200 mm * 850 mm, this Vertical Machining Center ensures efficient machining of complex parts with exceptional precision.

Manufacturing Capability

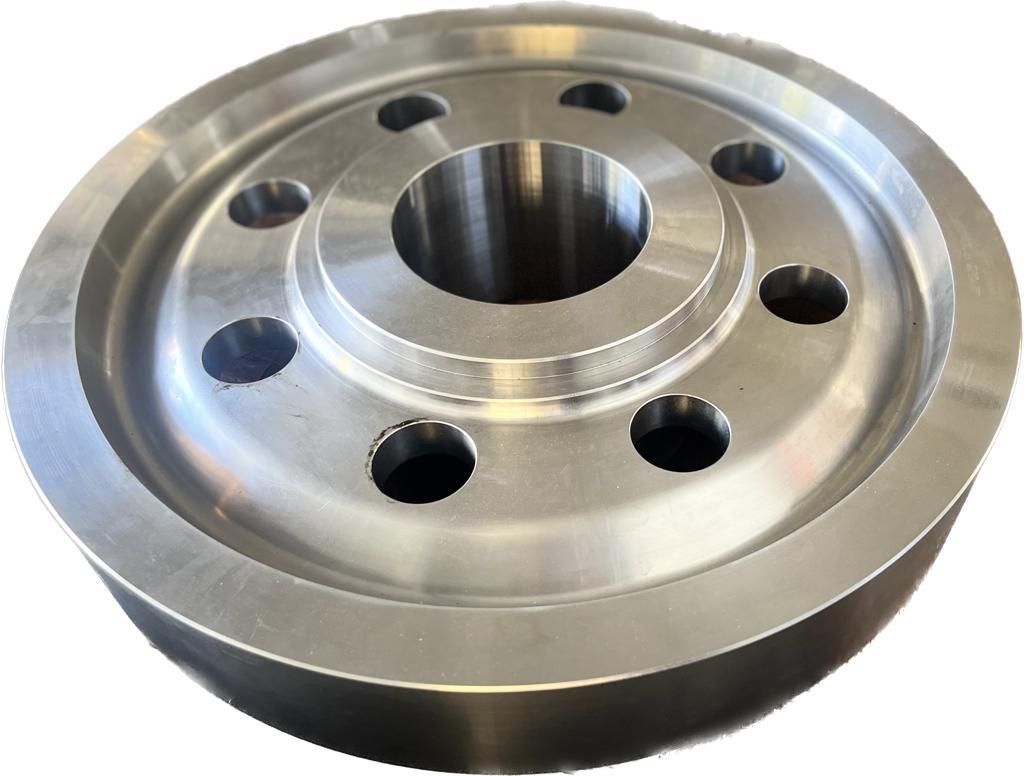

- Bright Bar with Machining: We provide precision machining services for bright bars, ensuring the perfect finish and accuracy required for critical components in diverse industries.

- Forged Bar with Machining: Our advanced machining capabilities enable us to handle forged bars with precision, delivering components that meet strict dimensional requirements and tolerances.

- Forging with Machining: With a combination of forging and machining expertise, we offer a seamless process for producing high-quality components with superior strength and durability.

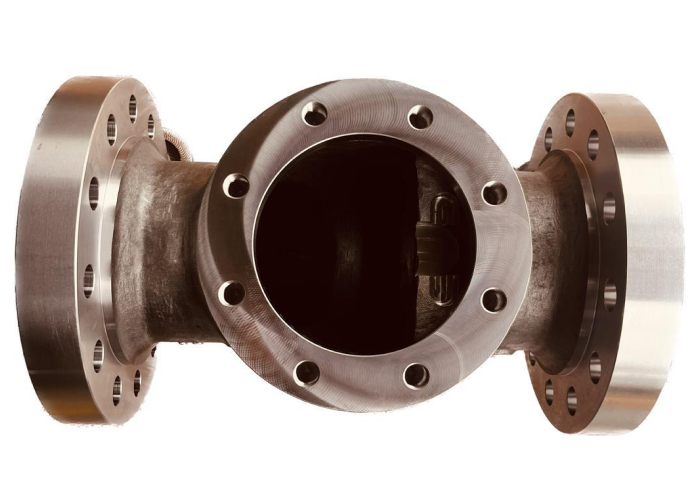

- Investment Casting with Machining: We excel in machining components made through investment casting, ensuring intricate details and excellent surface finishes for even the most complex parts.

- Casting with Machining: Our skilled team delivers precision machining for cast components, optimizing their performance, and ensuring seamless integration into various applications.

o

Quality Control Facilities

- Electronic Height Gauge (Trimos V-Plus): Our Trimos V-Plus Electronic Height Gauge allows us to measure heights, diameters, and distances with utmost precision.

- Surface Roughness Tester: Our Surface Roughness Tester enables us to evaluate the surface texture and finish of machined components. It’s helps us maintain the desired level of smoothness and quality for optimal performance.

- Gauges & Instruments: We offer a wide selection of precision gauges and instruments to verify various dimensions.

- Hardness Tester: With this device, we can verify the material’s suitability for specific applications and ensure components meet the necessary hardness requirements.

Material Handling Experience

- High & Low Steel Alloys: Whether it’s high-strength steel alloys or low-alloy steels, our precision machining capabilities enable us to deliver components that withstand demanding conditions and ensure optimal performance.

- Stainless Steel: Our profound understanding of various stainless steel grades ensures components with excellent corrosion resistance and mechanical properties.

- Titanium: We specialize in machining titanium, a lightweight and high-strength material used in industries that require exceptional performance and reliability.

- Brass, Manganese & Copper: Our expertise extends to manganese, and copper components, providing precise and durable solutions for various applications.

- Aluminum: With our CNC machining capabilities, we create components from various aluminum alloys.